Features and functions of precast panel machines

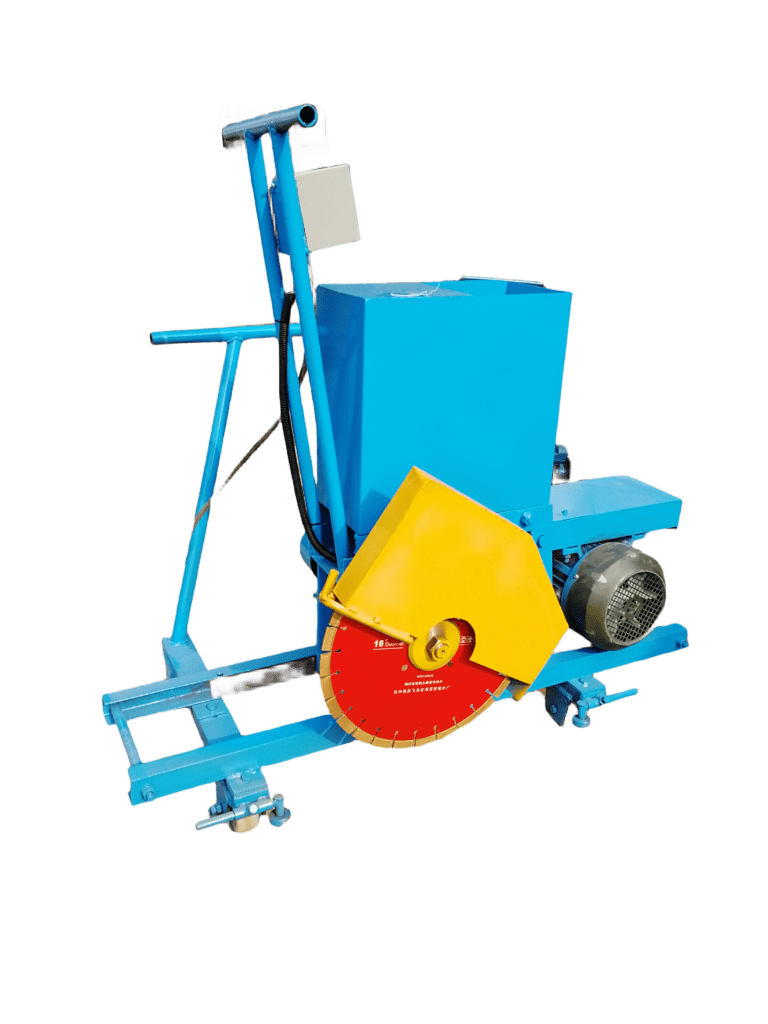

Precast slab machine is a specialized piece of equipment designed to produce precast concrete slabs efficiently and with consistent quality. These machines are commonly used in the construction industry to manufacture slabs for walls, floors, and other structural components. Here’s an overview of its features and functions:

Key Features:

Automation: Modern machines are automated to reduce manual labor and ensure uniformity in slab production.

Versatility: They can produce different types of slabs, such as hollow-core, solid, or ribbed slabs, depending on the mold and machine setup.

High Efficiency: Designed for mass production, enabling large-scale construction projects to maintain tight timelines.

Customizability: Machines often allow adjustments in slab thickness, width, and reinforcement patterns to meet project specifications.

Quality Control: Ensures consistent concrete mixing, compaction, and curing for high-strength, durable slabs.

Typical Workflow:

Concrete Feeding: Concrete mix is poured into the machine.

Shaping and Molding: The machine molds the concrete into slabs using pre-designed forms.

Reinforcement: Incorporates reinforcement bars, wires, or mesh for structural integrity.

Curing: Slabs are allowed to cure in a controlled environment to achieve required strength.

Cutting and Finishing: Once cured, slabs are cut to the desired size and polished, if necessary.

Applications:

Residential and commercial building construction.

Industrial facilities and warehouses.

Infrastructure projects such as bridges and tunnels.

If you’d like, I can provide additional details, diagrams, or recommendations about manufacturers and models of precast slab machine. Let me know!

If you want to buy a precast concrete panel machine with good quality and high cost performance, I recommend you to come to Henan Kelai Industrial Co., Ltd.