In the era of industrialized construction, precast concrete manufacturing equipment has emerged as a cornerstone for efficient and sustainable building practices. Among these innovations, precast panel production machines for construction stand out for their ability to deliver high-strength, dimensionally precise concrete components. Let’s explore how these technologies are reshaping the global construction landscape.

1. Core Features of Precast Panel Production Machines

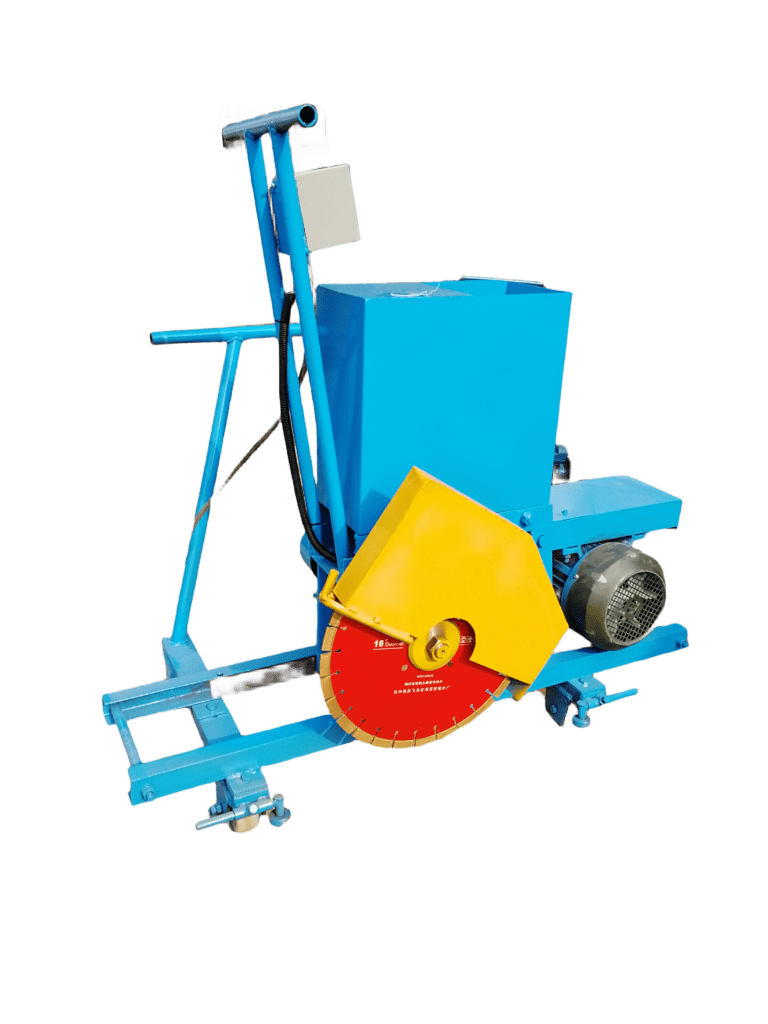

Automated Precision: Advanced precast concrete manufacturing equipment integrates automated mixing, molding, and curing systems to ensure consistent quality. For example, vibration technology eliminates air bubbles, enhancing structural integrity .

Modular Design Flexibility: These machines support customizable molds for diverse applications—from hollow-core slabs to insulated wall panels—enabling rapid adaptation to project specifications .

Material Optimization: By incorporating volcanic ash or lightweight aggregates, the equipment reduces material waste while improving thermal insulation and fire resistance .

2. Key Applications in Modern Construction

Residential & Commercial Buildings: Precast panels are widely used for floors, walls, and facades. Their factory-controlled production ensures compliance with seismic and acoustic standards, as seen in high-rise projects .

Infrastructure Projects: Bridges, tunnels, and highway barriers benefit from the durability of precast panel production machines, which deliver components resistant to environmental corrosion .

Green Building Solutions: Precast systems align with circular economy principles by minimizing on-site waste and enabling energy-efficient building envelopes .

3. Advantages Over Traditional Methods

Time Efficiency: A single precast concrete manufacturing equipment line can produce 1.3–1.7 meters of panels per minute, slashing project timelines by 50% compared to cast-in-situ methods .

Cost Reduction: Factory automation reduces labor dependency and lowers logistics costs, especially for large-scale projects .

Sustainability: Steam-curing systems and recycled material integration cut carbon footprints, aligning with global green certification standards like LEED .

4. Global Market Trends

The demand for precast panel production machines for construction is surging, driven by urbanization in Asia and infrastructure renewal in Europe. Leading manufacturers now offer IoT-enabled equipment for real-time monitoring, ensuring compliance with international standards such as CE-CPR and ICC-ES .

Conclusion

As the backbone of modern construction, precast concrete manufacturing equipment combines precision, efficiency, and sustainability. Whether for residential complexes or industrial facilities, these machines empower builders to meet tomorrow’s challenges today.

Explore our range of certified precast solutions – designed to elevate your projects while adhering to the highest industry benchmarks.

For technical specifications or customized configurations, [contact our team] to learn how our precast panel production machines can transform your construction workflow.

Keywords Embedded: Precast concrete manufacturing equipment, Precast panel production machine for construction.

To produce precast concrete wall panels, using the machinery of Henan kelai industrial co., ltd ,It is your best choice in this life.Believe that precast concrete panel production line machines can help you realize your building dream!