Precast concrete panel machine leads the innovation of the construction industry

As the construction industry’s requirements for construction efficiency and quality continue to increase, precast concrete panel machines are gradually becoming the “secret weapon” in engineering projects. This article will give you a detailed introduction to the technical advantages, application scenarios and future development trends of precast concrete panel machines, and will also specifically incorporate the keywords Precast concrete manufacturing equipment and Precast panel production machine for construction to help overseas customers better understand this cutting-edge equipment.

Industry background and development trends

In recent years, the construction market has increasingly urgent needs for green environmental protection, low-carbon energy saving and efficient construction. Although the traditional on-site casting method is mature, it has certain limitations in terms of construction cycle, engineering quality, environmental protection and energy saving. As an advanced Precast concrete manufacturing equipment, the precast concrete panel machine is gradually replacing traditional processes with its advantages of standardized production, stable process and controllable quality, and promoting the transformation of construction methods to factory-based and modular directions.

Technical advantage analysis

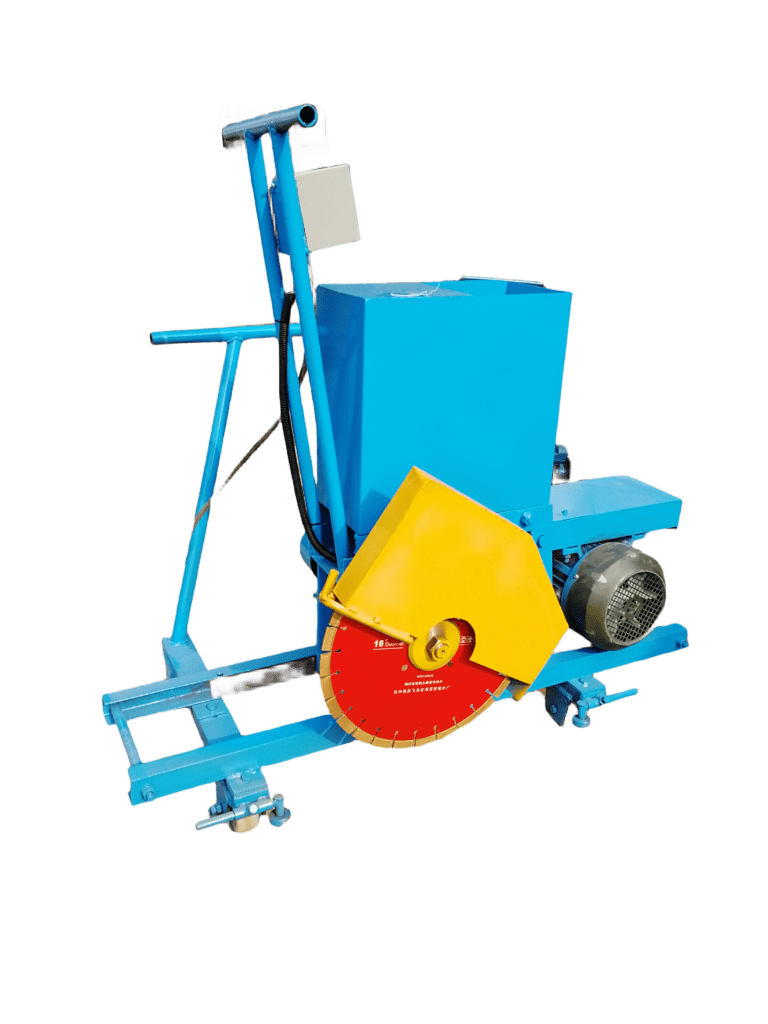

The precast concrete panel machine adopts advanced CNC technology and automated control systems to achieve mechanized operation of the entire process from concrete batching, pouring to curing and forming. Its main advantages include:

High production efficiency: The equipment has a high degree of automation, which greatly reduces manual operation and improves overall production efficiency.

Stable and reliable quality: The precise control system ensures that the size and strength of each precast panel are consistent, providing solid protection for construction projects.

Environmental protection and energy saving: Factory production reduces dust and noise during on-site construction, while saving energy consumption.

Flexible and diverse design: By adjusting the mold and process parameters, the precast concrete panel machine can produce components of various specifications and shapes to meet the needs of different projects.

At the same time, as a Precast panel production machine for construction, the equipment not only optimizes the production process, but also provides technical support and innovative ideas for the standardization and modular construction of construction projects.

Wide application scenarios

Precast concrete panel machines have been widely used in multiple construction fields, mainly including:

Residential and commercial buildings: The production of large quantities of precast concrete panels makes the construction of building structures more efficient, shortens construction periods and reduces costs.

Public works: Public facilities such as schools, hospitals, and gymnasiums achieve high-quality construction standards through factory production of precast components.

Infrastructure construction: In infrastructure projects such as bridges, tunnels, and subway stations, the use of precast concrete panels has greatly improved the durability and seismic resistance of the project.

Overseas engineering market: In response to the international market’s requirements for building quality and construction speed, advanced Precast panel production machine for construction is attracting more and more attention from overseas customers and has become an important equipment for major engineering projects.

Market prospects and future prospects

Looking ahead, the application of precast concrete panel machines will continue to expand and show broad prospects in the following aspects:

Intelligent manufacturing and digital transformation: Combined with the Internet of Things, big data and artificial intelligence technologies, precast concrete panel machines will achieve a higher level of automation and intelligence, further improving production efficiency and product quality.

Standardization and modular development: With the continuous improvement of construction industry standards, precast component production will tend to be standardized, and modular construction mode will become the mainstream trend of the future construction market.

International market expansion: With its environmentally friendly, efficient and stable quality characteristics, precast concrete panel machines will better meet the needs of the global market and provide high-quality equipment support for overseas construction projects.

Conclusion

As an advanced Precast concrete manufacturing equipment and Precast panel production machine for construction, precast concrete panel machines are constantly promoting the innovation of construction methods. By improving production efficiency, ensuring project quality and energy saving and environmental protection, this equipment is gradually changing the production model of the construction industry and ushering in a broader development prospect. Both large-scale domestic and foreign engineering projects and the development of emerging markets will benefit greatly from this technological change.