Precast Concrete Panel Machine: Working Principle and Manufacturing Process Explained

As construction projects around the world demand faster delivery, better quality, and lower costs, precast concrete panels have become a preferred building solution. But how exactly are these panels made? And what role does the precast concrete panel machine play in the production process?Precast concrete panel machine working principle will tell you !

At Henan Kelai Industrial Co., Ltd., we’ve been manufacturing advanced precast concrete panel machines for over 20 years. In this article, we explain the working principle, machine components, and panel production process so you can better understand how to invest in and operate these powerful machines.

🔧 What Is a Precast Concrete Panel Machine?

A precast concrete panel machine is industrial equipment used to produce concrete wall panels in a controlled environment. These panels are cast, cured, and prepared off-site (in a factory), and then transported to the construction site for fast assembly.

Kelai’s panel machines are designed to produce:

- Solid wall panels

- Hollow core panels

- Lightweight sandwich panels

- Composite Acotec panels

- Partition or load-bearing walls

Each type of machine is built to match specific panel thickness, material mix, and output capacity.

⚙️ Working Principle of Precast Concrete Panel Machines

Though panel machines can differ by type, the core working principle follows this sequence:

1. Material Preparation and Feeding

The process starts with raw materials such as cement, sand, stone, lightweight aggregates (e.g., EPS or ceramsite), and water. These materials are automatically batched, mixed, and delivered to the machine’s hopper.

2. Panel Forming and Shaping

Once the mixture enters the mold chamber, the machine uses high-frequency vibration, hydraulic compaction, or screw extrusion (depending on model) to shape the material into panel form.

Kelai’s extrusion-type machines are ideal for producing long continuous panels on a steel platform, which are later cut into specified lengths.

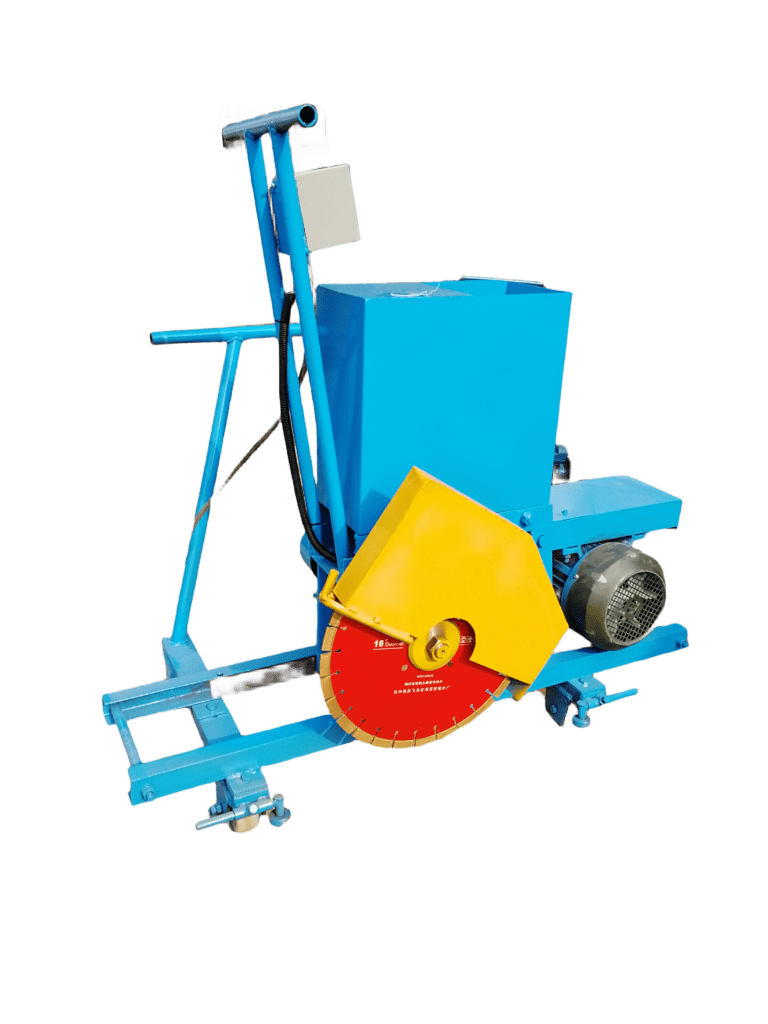

3. Panel Cutting

Once formed, the panels are automatically or manually cut to the desired length using a cutting system integrated with the machine or placed alongside.

4. Demolding and Stacking

After initial curing or setting, panels are carefully demolded and stacked using lifting equipment or conveyors. Some machines offer auto-stackers to increase efficiency.

5. Curing

Panels are moved to a curing area or curing room where they gain strength over 8–24 hours. Accelerated curing using heat or steam is optional, depending on the project.

🏭 Machine Components Overview

A complete precast concrete panel production line includes:

- Material batching and mixing system

- Conveying system (screw or belt type)

- Forming/extrusion machine

- Hydraulic or mechanical mold press (if applicable)

- Cutting device

- Mold platform or forming table

- Curing rack or room

- Control panel / PLC system

All components work together to ensure continuous, precise, and scalable panel production.

🚀 Advantages of Kelai Panel Machines

Henan Kelai Industrial Co., Ltd. offers several models of precast concrete panel machines with the following features:

- ✅ 12+ panel types supported, from 60mm to 200mm thickness

- ✅ High-frequency vibration ensures density and surface finish

- ✅ Customizable molds for different panel shapes and lengths

- ✅ Efficient output from 200–1200 square meters per day

- ✅ Stable mechanical design with long-life wear parts

- ✅ Low energy consumption and user-friendly interface

Whether you’re producing lightweight walls for low-cost housing or high-strength structural panels, Kelai offers solutions for every scale.

🌍 Application Fields

Precast concrete panels made with Kelai machines are used in:

- 🏘️ Affordable housing developments

- 🏢 Modular buildings and apartments

- 🏫 School, hospital, and public projects

- 🧱 Boundary walls, fencing, and retaining walls

- 🏭 Industrial plants and prefab offices

We have clients in over 30 countries including Nigeria, Egypt, Indonesia, Bangladesh, Saudi Arabia, and Russia using Kelai machines for local mass production.

📦 Want to Set Up a Precast Panel Production Line?

If you’re planning to launch a precast panel business, or want to upgrade from manual production to semi- or fully-automatic lines, we’re here to help.

At Kelai Machinery, we provide:

- ✅ Complete plant layout and machine recommendation

- ✅ Detailed machine specification sheet

- ✅ On-site or remote installation support

- ✅ Lifetime after-sales service

📞 Contact Us for a Customized Proposal

📧 Email: kelaimachine@gmail.com;

🌍 Website: www.kelaiii.com

📱 WhatsApp: +86 17788171295

Let Kelai help you produce high-quality precast concrete panels for faster, more efficient construction.

Precast Concrete Wall Panel Extruder Machine for Sale | Kelai Manufacturer