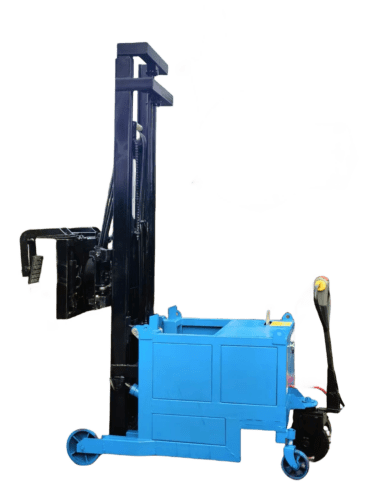

Hydraulic Wall Panel Installation Machine

Overview Of Hydraulic Wall panel installation machine

About Wall panel installation machine

We have been engaged in the research, development, and manufacturing of precast concrete machinery and equipment for more than 20 years. According to customers’ feedback and suggestions, we developed the first generation of Acotec Wall panel installation machine in 2010. After10 years of continuous improvement, we have designed more than ten models of the wall panel installation machines to meet the different types of wall panel installation and construciton requirements.

Machine Description

This wall installation machine is specially used to carry and erect precast lightweight concrete|Acotec|EPS|ALC|AAC wall panels and other types of interior and exterior partition wall panels. It is a very practical wall panel lifting machine equipment, which is widely loved by construction and installation contractors.

- The machine is a combination of electric and hydraulic power.

- The panel installation machine is used for moving and lifting the wall panel in the construction site and lifting the panel into the upright position.

- The panel is moved into the correct place by the wall panel installation trolley and lifted for installation.

- The machine is moved and drove automatically. Lifting the panel is hydraulically operated with the handheld control device.

- The panel is first picked up from the horizontal position and then rotated to the vertical position.

- The machine is Battery operated, charging device 120 – 230 VAC / 50 / 60 Hz with a plug connection. After a full charge, the machine can work continuously for 8-10 hours

- The biggest loading capacity of the machine that we design and manufacture can lift and install Max. panel weight 1000kg, width 600mm, length(height) 7200mm.

- There are different models of installation machines designed for the different installation sites. For example, we designed and manufacture the compact size of wall panel installation trolley specially used for the wall panel installation in the apartment rooms

Advantages of wall installing machine

- Reduce the labor intensity by using hydraulic oil cylinders to complete the grasping, handling, and installation of the panel.

- Reduce the damage to the panel by using hydraulic clamps and left and right hydraulic side shift systems to complete the installation and splicing at the same time.

- Improve work efficiency, save labor

- Ensure the personal safety of installation workers

Wall panel installation machine

Models of wall installaiton machines

We have more than ten models of this machines, which can meet the work needs of customers at different wall panel construction sites, such as, residential buildings, apartments, commercial buildings, office buildings, hospitals, factory warehouse buildings, basements, etc.

Features and Functions

Forklift function

Wall panel Alignment

Horizontally picking-up wall panels etc.

Wall panel 360°Rotation

Side- shift clamping arm

Grab the wall panel and lift it up and down

Joining panels: upper panels 4 meters+ lower panels 4 meters

Alignment of wall panels front and back

Double lift slide Clamp design

Installation machine production photos

Working Principle of Wall Panel Installation Machine

Electric Drive System

A DC 48V drive battery is used to power the installation machine. The use of the electric drive axle effectively reduces the labor intensity of workers in the process of carrying the panel. The drive motor of the wall panel installation trolley can be controlled through the handbrake handle, and there is a power cut-off in the event of an emergency.

Hydraulic power system

The power output of the hydraulic cylinder is generated from the battery. The hydraulic cylinder produces high-pressure oil to operate the five-link hydraulic directional valve to control the lifting, support, left and right side shift, 360- degree rotation, and the hydraulic clamp of the wall panel installation machine.

Left, right, forward, and backward shift device

The steering handle is used to control the movement of the wall panel installation trolley left, right, forward and backward.

360-degree rotating device

The 360-degree rotating device enables the panels to be installed horizontally or vertically. So the wall panel installation machine works more flexibly。

Hydraulic clamp

The wall panel installation machine can bring the panel to the installation area to complete the joining work between the panel to panel.

Hydraulic support device

Due to the different lengths of the panels to be installed, the required installation height is also different. In a limited space of installation and transportation, the rear tilt support function is used to reduce the height of the wall installation machine

Other Supporting machines for making concrete Wall Panel Machine